Gear Coupling

Roto Gear Flexible Gear Couplings

Roto Gear Curved Tooth Couplings are suitable for any

conceivable mechanical power transmission drives in all

industries, large / medium / small. It is compact and lighter

and thus suitable for installation where space is a constraint.

Roto Gear Couplings mainly comprises two Hubs with external

machine-cut teeth of specially designed configuration, two

flanged sleeves with internal teeth to match the two Hubs and a

set of machine finished fasteners to both the two Flanged

Sleeves when in installed position. Specially designed sealing

arrangement is provided to prevent leakage of grease and ingress

of outside dirt/water.

Roto Gear Couplings have its components manufactured out of

properly treated steels of quality which are best suited for all

industrial mechanical power - transmission systems. Teeth

profile are of specially designed configuration to provide ample

mechanical flexibility and compensation of parallel, angular and

axial misalignment of the connected shafts.

Roto Gear Couplings are available in following executions:

FULL GEARED FLEXIBLE TYPE ● HALF GEARED FLEXIBLE TYPE ● MILL MOTOR TYPE ●

SPACER TYPE ● FLOATING SHAFT TYPE ● BRAKE DRUM TYPE ● VERTICAL TYPE

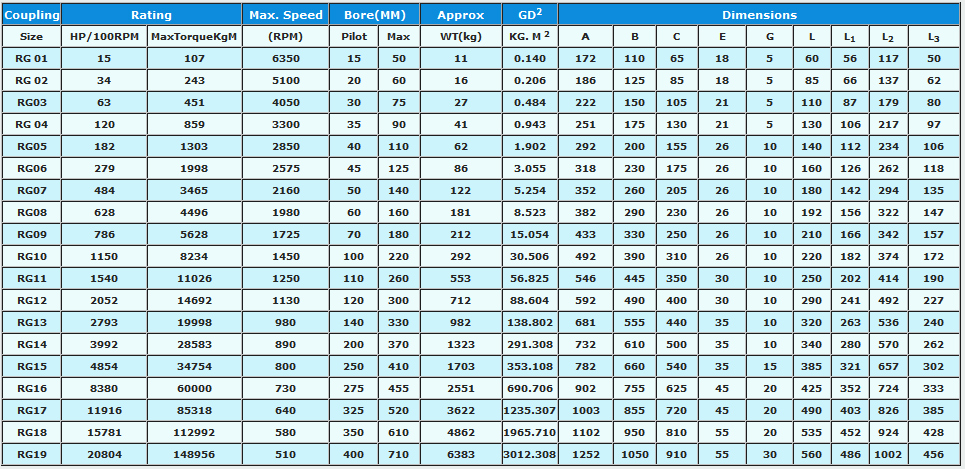

Selection

■ Select the Roto Gear Coupling of size that ill accommodate the diameter of the larger shaft of a drive.

■ To ensure above coupling so selected has the required rating capacity:

a) Check the service factor applicable to the drive from the service Factor Chart

b) Find out the Rating HP/100RPM of the drive as per the following formula:

HP X Service Factor X 100

---------------------------------- = HP/100RPM

RPM

c) Check that the rating : HP/100 RPM of the selected Coupling is either equal to, or, great than the calculated rating as above.

Minimum Clearance Required for Aligning